The use of plastic pipes in the construction industry continues to rise, with PVC, PEX and HDPE pipes used increasingly over steel and copper pipes. While these plastic polymers are cheaper to install, new research suggests they may be more costly in the long run.

Working with the Alliance of British Insurers (ABI), the Alliance for Sustainable Building Products (ASBP) has published a new report that looks at the escape of water in buildings due to the failures of plastic pipes.

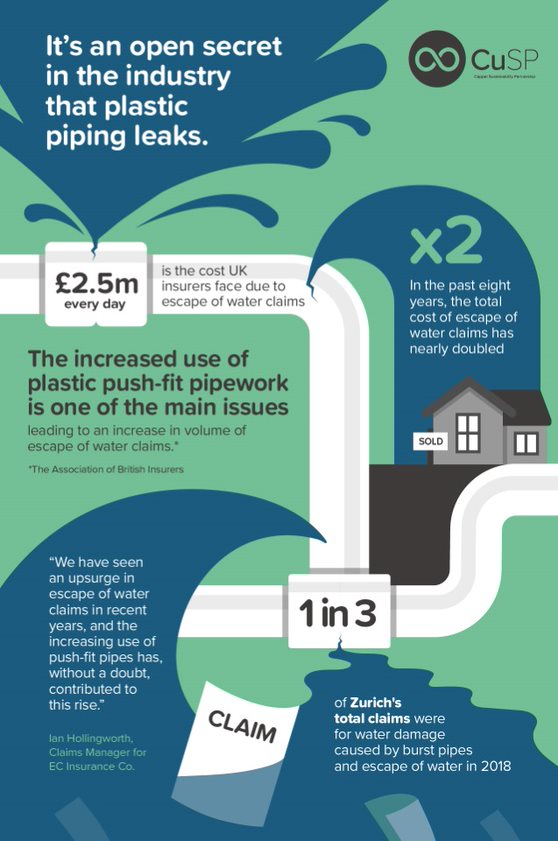

In the past eight years alone, the total cost of escape of water claims has nearly doubled, with these claims currently costing UK insurers £2.5 million a day. Other types of property claim have generally trended downward in this period.

The report, which draws on data from the UK insurance industry, cites plastic push fittings as one of the main causes of this upturn.

Why are water leaks on the rise?

After conducting interviews with insurance companies, loss adjusters, forensic scientists and risk management consultancies, the ASBP has identified several reasons for the upswing in escape of water claims.

More plumbed appliances

One of the more straightforward explanations for the increase in escape of water claims is that the number of plumbed appliances in the average building is on the rise.

Most new-build homes are equipped with dishwashers and washing machines, as well as multiple showers and toilets, with this increase making water leaks more likely.

Integrated plumbing

Another notable trend in the plumbing profession is the rise of integrated plumbing systems. These are used to conceal unsightly pipework behind walls and panels, typically in bathrooms.

Because integrated plumbing systems are concealed, leaks are usually not noticed until a significant amount of damage has been caused, increasing costs for insurers.

Material incompatibility of plastic pipes

Another area in which the report raises concerns with plastic plumbing is that of material incompatibility.

Plastic pipes are subject to failure when they encounter incompatible materials, which can include caulks, paints, sealants, pipe tapes, leak detection fluids and fire-stopping materials.

Research carried out by forensic investigation firm Hawkins indicates that CPVC pipes, a type of thermoplastic pipe used widely in fire sprinkler systems, become brittle when used in conjunction with incompatible fire-stopping compounds.

Environmental stress cracking can occur when the incompatible materials come into contact, causing cracking in the pipework itself rather than the fittings where most failures occur.

The report observes that a growing number of CPVC manufacturers now provide guidance on materials that are incompatible with their pipework.

Finding solutions to the plastic problem

Cheaper and easier to install, plastic fittings are often preferred over traditional materials like copper and steel in new builds. However, as research from the insurance industry shows, plastic plumbing often comes with an outsized cost.

While there are some applications where plastic pipes are most suitable, the increase in water leaks directly linked to plastic push fittings is leading the construction industry to consider alternatives.

The CHARM ‘virtually plastic-free homes’ project, which aims to substitute plastic pipes for alternative materials wherever possible, has seen a significant reduction in plumbing defects when compared with the average new build.

It’s hoped that the report will encourage higher standards in plumbing installation, helping to curb the increase in water leaks and save the industry millions in maintenance costs.

Want to learn about the copper vs plastic pipes debate? Make sure to check out our other news items or subscribe to our newsletter.