Copper vs plastic pipes

Jump to section

The debate between copper vs plastic pipes has been ongoing in the plumbing industry for many years. Copper pipes have long been hailed the gold standard in plumbing but, despite this, plastic pipes have become increasingly prevalent in recent years.

With contractors under pressure with fixed-price contracts, some are looking to substitute products for cheaper alternatives and plastic pipe manufacturers have pushed their product forward as a solution.

While it is true that plastic pipes provide a cheaper alternative to metal, there are several serious environmental problems and installation weaknesses to this solution that most manufacturers have sought to gloss over.

Copper pipes, which have been used for millennia without issue, are the superior choice for plumbers and homeowners looking for the best pipes for plumbing in terms of quality, safety and sustainability.

Types of pipes used in plumbing

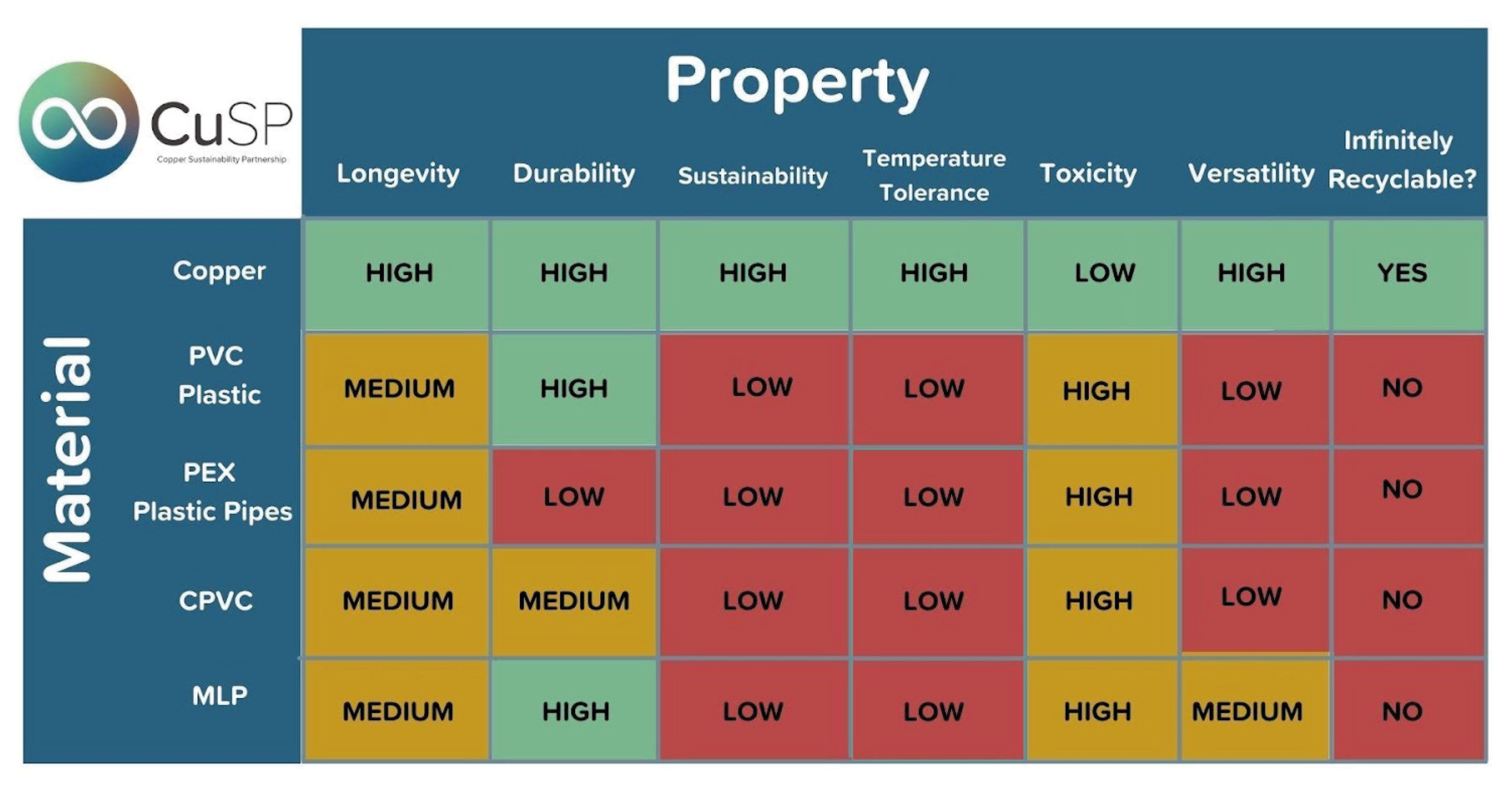

There’s a range of factors to consider when choosing the best type of pipe to use in plumbing and construction. Here’s a breakdown of four common types of plastic and how their properties compare to copper pipes.

Copper pipes

Known for their exceptional durability, resistance to corrosion and a multitude of other benefits, copper plumbing pipes can last for decades and are naturally anti-microbial. Better yet, they are infinitely recyclable and do not lose any of their benefits during the copper recycling process.

With its ability to withstand extreme temperatures, pressures and exposure to UV and oxygen, copper can be used for a range of purposes and across a multitude of environments, without its integrity being altered.

Polyvinyl chloride (PVC)

PVC is a combination of plastic and vinyl and is a popular choice for mains water lines. However, PVC pipes are not as flexible as some other types of plastic pipes. Additionally, because PVC warps and can melt temperatures of around 60°C, PVC pipes cannot be used for supplying hot water or heating to buildings.

Cross-linked polyethylene (PEX)

Unlike copper, PEX cannot be recycled at all as it doesn’t melt down like other types of plastic. When used for plumbing, PEX pipes can’t be directly connected to a water heater, as they require 18-inches of a heat-resistant material – usually copper – to be connected to the water heater before it is connected further down the line.

In addition to this, PEX pipes are only suitable for indoor use as they can be damaged by sunlight. It is one of many types of plastic that has been flagged for contamination caused by thermal degradation, and often affects taste and odour of drinking water.

Chlorinated polyvinyl chloride (CPVC)

Common in industrial plumbing, CPVC plastic pipes are PVC pipes which are treated with chlorine. While this makes CPVC pipes better at handling hotter temperatures and pressures than standard PVC, this plastic tends to crack when subject to colder temperatures and will break down when exposed to sunlight for extended periods of time.

This makes it an unsuitable material to use for plumbing pipes that need to be outside or underground, such as water mains, which is not the case for copper pipes.

Multi-layer plastic pipes

Multi-layer pipes are made using two thin layers of plastic – typically a form of polyethylene (PE) – with a layer of aluminium in between. This material is complex in terms of recycling, as it is virtually impossible to separate both materials, even if the plastic was reusable. Like many plastics, the outer coating can be damaged by UV rays which reduces its use to indoor only.

The advantages of copper vs plastic pipes

From durability and versatility to safety and sustainability, there’s a multitude of reasons to favour copper in the debate between copper vs plastic pipes.

Copper pipes are infinitely recyclable

Copper pipe has a unique ability to be safely recycled over and over without any loss in performance or properties. It’s estimated that around two-thirds of the 550 million tonnes of copper produced since 1900 are still in use today.

Though copper recycling rates vary from country to country, recycled copper already meets more than 30% of global copper demand. In Europe, half of the region’s demand for copper is currently being met with recycled materials, and there is room for recycling rates to grow further.

Despite industry claims that plastic pipes are fully recyclable and have a circular, end-of-life economy, most plastics are still not being recycled. Only around 9% of global plastic waste is recycled, while 50% ends up in landfill.

One reason for this is that many plastic pipes aren’t recyclable. For example, multi-layer composite (MLC) tube, consisting of layers of plastic and aluminium, is a prime example of a commonly used plumbing material that cannot be recycled.

Additionally, plastic compounds such as PVC, PEX and PE all deteriorate over time, making them less and less suitable for recycling.

According to the University of Wisconsin-Madison, around 100 million tonnes of multilayer thermoplastics are produced globally each year and, because there is no way to separate the polymers, almost all of that plastic ends up in landfill or incinerators.

Many claim that multilayer plastic pipes are recyclable but, as it stands, there are no recycling frameworks in place, so its ‘recyclability’ is currently nothing but theoretical.

Learn more about the sustainability credentials of copper and plastic pipes

Copper pipes are much safer

Copper is known for its thermal resilience and its ability to withstand fluctuating temperatures. In fact, its incredibly high melting point means copper plumbing pipes won’t melt, burn or give off toxic fumes in a building fire, like some plastic pipes will.

An official building code report published by the International Code Council cites plastic material like piping as a “dangerous void” because of how it can melt, burn, and spread fires. Many plastics are intumescent materials, which means they grow in size in the event of fire, which can create extreme fire hazards because of how they allow fires to spread.

Additionally, plastic pipes have been known to allow pesticides and other soil contaminants through into drinking water and studies have shown that certain types of pipes containing plastic can leach MTBE, a toxic petroleum by-product, into drinking water.

However, antimicrobial copper has been proven to support health and well-being as its naturally occurring anti-bacterial properties discourage the growth of harmful organisms. Unlike synthetic plastic pipes, copper pipes are also completely natural so don’t emit contaminants or synthetic compounds into drinking water.

Learn more about the fire safety credentials of copper and plastic pipes

Copper pipes last a lifetime

Plastic isn’t as durable as copper, which means that plastic pipes are likely to need replacing before copper pipes. The general consensus in the plumbing industry is that copper pipes tend to last around 20 years longer than plastic pipes.

Copper is favoured for products that need to keep their integrity for hundreds of thousands of years. For example, copper makes up part of Sweden’s nuclear waste handling technology where copper canisters encapsulate the radioactive waste for long-term storage. The canisters are required to keep their integrity for at least 100,000 years but are thought to last five times longer.

With use in domestic and industrial products that must maintain their reliability for generations, it’s clear that copper is a durable engineering solution for now and future generations.

Copper pipes are extremely versatile

Copper pipes are incredibly versatile and can be used across utilities including water, heating, gas and air conditioning, all while offering greater choice and longevity. Across these different settings, copper pipes can be bent and shaped to fit tight spaces behind walls and beneath flooring.

Plastic pipes are unsuitable for use in outdoor environments as the plastic can be damaged by UV radiation, and they can’t be used in steam services, solar applications, next to a boiler or in medical gas installations.

With its ability to withstand extreme temperatures, pressures and exposure to UV and oxygen, copper can be used for a range of purposes and across a multitude of environments, without its integrity being altered.

These include water pipes, radiator pipes and pipes for air source heat pumps in homes and offices, as well as medical copper pipes in hospitals.

Frequently asked questions

Why is copper used for water pipes?

Copper is durable and corrosion-resistant, meaning copper pipes can be used for many decades with minimal maintenance. Naturally antimicrobial, copper also keeps water safe by killing bacteria and viruses on contact. Finally, copper is a malleable material that can be shaped to fit tight spaces in walls and flooring.

Why is copper used for radiator pipes?

Copper has several properties that make it a suitable material for central heating pipes. Firstly, copper has an exceptionally high thermal conductivity, ensuring heat is transferred efficiently with minimal energy loss. Robust and durable, copper pipes are also unlikely to cause potentially hazardous leaks.

How long do copper pipes last?

Copper is an incredibly durable material, with high-quality copper pipes having a typical life expectancy of 70–80 years. This is considerably longer than most plastic pipes, which generally last around 50–70 years before needing to be replaced.