Copper pipes remain a top choice for plumbing in homes across the UK, thanks to their strength, longevity, and safety features. Learning how to solder copper pipes is a valuable skill for anyone tackling DIY projects or maintenance. Soldering creates strong, reliable joints that stand the test of time, far outlasting the connections in plastic pipes, which can loosen or fail under pressure.

Why Choose Copper Pipes for Your Plumbing Needs

Copper pipes offer clear advantages over plastic ones, starting with their durability. They resist corrosion and handle high temperatures without warping or cracking, which makes them ideal for hot and cold water systems. Plastic pipes may seem cheaper at first, but they often need replacing sooner due to wear, leading to higher long-term costs and more waste. Copper, on the other hand, can last fifty years or more, and its natural antimicrobial properties keep water cleaner by reducing bacteria buildup.

Safety is another strong point. Copper does not burn or release toxic fumes in a fire, unlike plastic, which can melt and spread flames. To dive deeper into what makes copper special, check out our page on copper properties.

Tools and Materials Needed for Soldering Copper Pipes

Before starting, gather the right equipment. You will need a propane or butane torch, solder wire suited for plumbing, flux paste, emery cloth or wire brush, a pipe cutter, and a deburring tool. Safety gear like gloves, goggles, and a fire extinguisher is essential too. Working with copper pipes in retrofitting projects often requires these basics too.

Clean preparation is key to a good solder joint. Cut the pipe to length with the cutter, then smooth the ends with the deburring tool. Use emery cloth to polish the outside of the pipe end and the inside of the fitting until they shine. This removes oxidation and ensures the solder bonds properly.

Step-by-Step Guide to Soldering Copper Pipes

Apply flux generously to both the pipe end and the fitting socket. Slide the fitting onto the pipe, twisting slightly for even coverage. The flux prevents oxidation during heating and helps the solder flow smoothly.

Heat the joint evenly with the torch, moving the flame around to avoid hotspots. Touch the solder to the joint once hot; it should melt and flow into the gap on its own. Continue until the joint is fully filled with a shiny ring of solder. Let it cool naturally without disturbing it.

Wipe away excess flux with a damp cloth once cool. Test the joint under pressure later to confirm it holds. Practice on scrap pieces first if you are new to this.

Soldering copper pipes creates joints stronger than the pipe itself, which is why professionals rely on it. Plastic push-fit alternatives may work for minor jobs but lack the same reliability for main water lines.

How to Fix a Leaking Copper Pipe Without Soldering

Sometimes a quick fix is needed for a leaking copper pipe without soldering. For pinhole leaks, use a copper repair sleeve or epoxy putty designed for plumbing. Clean the area thoroughly, apply the putty or clamp the sleeve in place, and let it cure as per instructions. This buys time until a proper solder repair can be done.

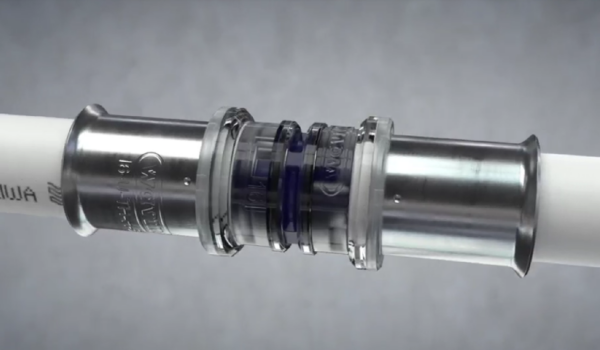

Compression fittings offer another no-solder option. Cut out the damaged section, slide on the olive and nut, insert a new pipe piece, and tighten. These work well for accessible spots but are not as permanent as soldered joints. For bursts, a pipe freezing kit stops water flow temporarily, allowing repairs without draining the system.

While these methods help, they highlight why copper’s robustness reduces leaks in the first place. Plastic pipes leak more often from fittings failing or material fatigue.

Soldering Copper Wire for Electrical Connections

Soldering copper wire follows similar principles but uses different tools. Strip the insulation, twist strands if multi-core, and tin the wire ends by applying flux and a small amount of solder with an electric soldering iron. Overlap or butt the wires, heat the joint, and flow solder to secure it. Insulate with heat-shrink tubing afterwards.

This method ensures low-resistance connections vital for safety in home electrics. Copper wiring outperforms alternatives in conductivity and fire resistance.

Maintaining Soldered Copper Pipe Joints

Regular checks keep soldered joints performing well. Look for discolouration or dampness around fittings annually. If issues arise, a re-solder fixes most problems quickly. Copper’s inherent qualities mean fewer repairs overall compared to plastic systems prone to cracking.

Mastering soldering copper pipes empowers homeowners to maintain reliable plumbing that prioritises safety, efficiency, and sustainability. Copper’s benefits make it worth the effort, delivering peace of mind for decades.