Firestopping is essential to building safety. Without properly installed firestops, smoke and flames can quickly travel through a building, damaging the property and endangering its occupants.

This is especially true with piping systems, which pass through walls, ceilings and floors, connecting different parts of a building and flowing through to external service lines.

Designing and installing firestops for piping systems is an incredibly complex process, with firestopping around plastics pipes presenting a number of unique challenges for engineers.

A new report from CuSP member, Safe Piping Matters, highlights some of the risks of firestopping plastic pipes compared to non-combustible alternatives like copper pipes.

The importance of firestopping around pipes

An integral part of plumbing, heating and fire sprinkler systems, pipes are used ubiquitously in building design, passing through walls, ceiling and floors.

Because pipes connect different parts of a building, they have the potential to quickly spread smoke and flames should they catch fire.

“Even the smallest void that’s not protected with proper firestopping almost acts like a blowtorch. You’re going to have really hot flames, gas, and smoke going through that opening…so it rapidly spreads the fire and smoke.” – Bruce Johnson, fire marshal at Underwriters Laboratories.

Failure of firestops can cause devastating tragedies. One of the most well-known examples is the 1980 MGM Grand fire, which killed 85 people when a wall of flames blew out the main entrance.

Such incidences can be avoided with proper installation of fire sealants and intumescent pipe collars, which expand to fill the gaps left by pipes, thereby halting the spread of the fire.

Heavy smoke engulfs the MGM Grand, 21 November 1980.

Firestopping different piping materials

Firestopping around pipes is fraught with regulations, and this is especially true for the design and installation of firestops for plastic pipes.

This is because plastic pipes – including PVC, CPVC, PEX and PE – will catch fire at a much lower temperature than non-combustible metal pipes.

More additions have to be made to plastic pipes to ensure they meet the latest safety standards, an important consideration for plumbers when picking between copper or plastic pipes.

In addition, different materials will be used, with plastic pipes fitted with intumescent materials that are designed to fill the space around the pipe after it melts.

Non-combustible metal pipes, on the other hand, are less likely to melt in the event of a fire and therefore require less modification.

The challenges of firestopping plastic pipes

Because plastic pipes melt and burn, the assembly must not only account for the space around the pipe, but for the space occupied by the pipe itself.

Most metal pipes will retain their structural integrity when subjected to extreme heat, making the assembly more straightforward.

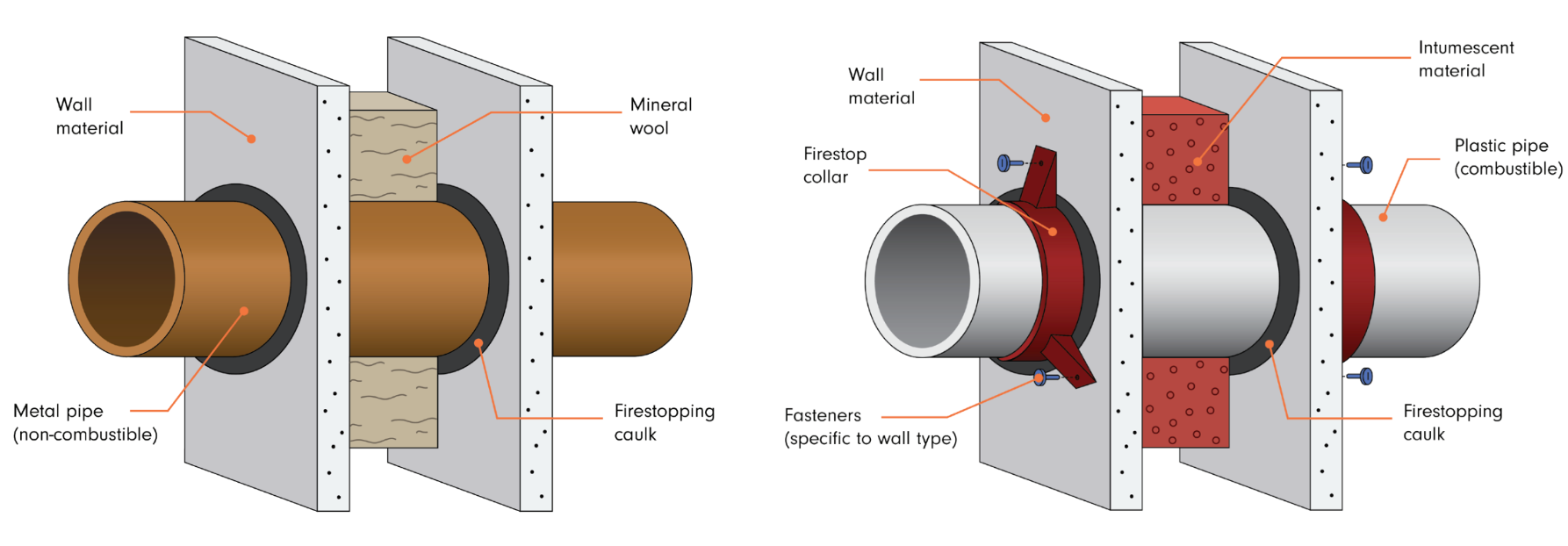

The firestop assembly for iron and copper pipes may only require these two components:

- Firestopping caulk, to fill the annular space around the pipe

- Fire-resistant material filling, to fill the annular space behind the pipe

In contrast, assemblies for plastic pipes may feature all the following:

- Firestopping caulk, to fill the annular space around the pipe

- Intumescent material filling, to fill the annular space behind the pipe as well as the space vacated by the pipe once it melts

- An intumescent pipe collar or other device, to secure the assembly to the wall

- Fasteners appropriate for the wall type, to ensure the pipe collar remains in place

As the number of firestopping components increases, so does the risk of failure. Just a single error in the design and installation of a pipe firestop can have a devastating impact on fire safety.

One of the most common causes of failures with plastic pipes stems from the interaction of firestopping materials with the pipe.

As Plastic Pipe and Fittings Association’s firestopping guide notes, “firestop sealants may contain chemical additives that can cause damage to plastic pipes”.

This means that if a firestopping material not compatible with the plastic pipe is used, a chemical interaction could weaken the pipe or cause it to fail prematurely, even during normal use.

Copper pipes: the safe choice

With a melting point that exceeds the temperature of the average building fire, copper is far superior to plastic when it comes to fire safety.

And while the safety of plastic pipes can be enhanced through firestopping, the complexity of this process can lead to potentially fatal errors.

The responsible choice for plumbers, engineers and architects is non-combustible metal piping that can be trusted to halt the spread of a fire.

Want to learn more about the fire safety credentials of different piping materials? Visit our fire safety page for more resources and insights.